Optimizing automation equipment with Quick Response solution

Maximize productivity in modern manufacturing with Advantech WISE-IoT Quick Response. By collecting real-time equipment data, it accurately evaluates OEE and uses Andon to swiftly address anomalies, ensuring minimal downtime and seamless production efficiency.

Advantages of Adopting the Starter Packages

Real-Time Notifications

- Enable real-time monitoring of equipment status and key production information, ensuring prompt notifications to production staff on their mobile devices addressing any abnormal events.

Production Transparency

- Easily monitor current production status through the dashboard, allowing the production line to communicate to managers through data.

Bottleneck Identification

- Maintain a clear record of production events for analysis to identify opportunities for improvement and optimization.

Feature Highlights

Data Pre-Processing

- Transform raw machine data into meaningful production information to help users identify and address production issues.

OEE & Event Visualization

- Utilize dashboard templates to calculate and visualize factory KPIs, including OEE and MTBF. This enables live insights to be accessible to both line and production management.

Andon Reports

- Andon allows customization of event types and setting of notification categories, enabling organized sorting and summarization of any abnormalities encountered during production.

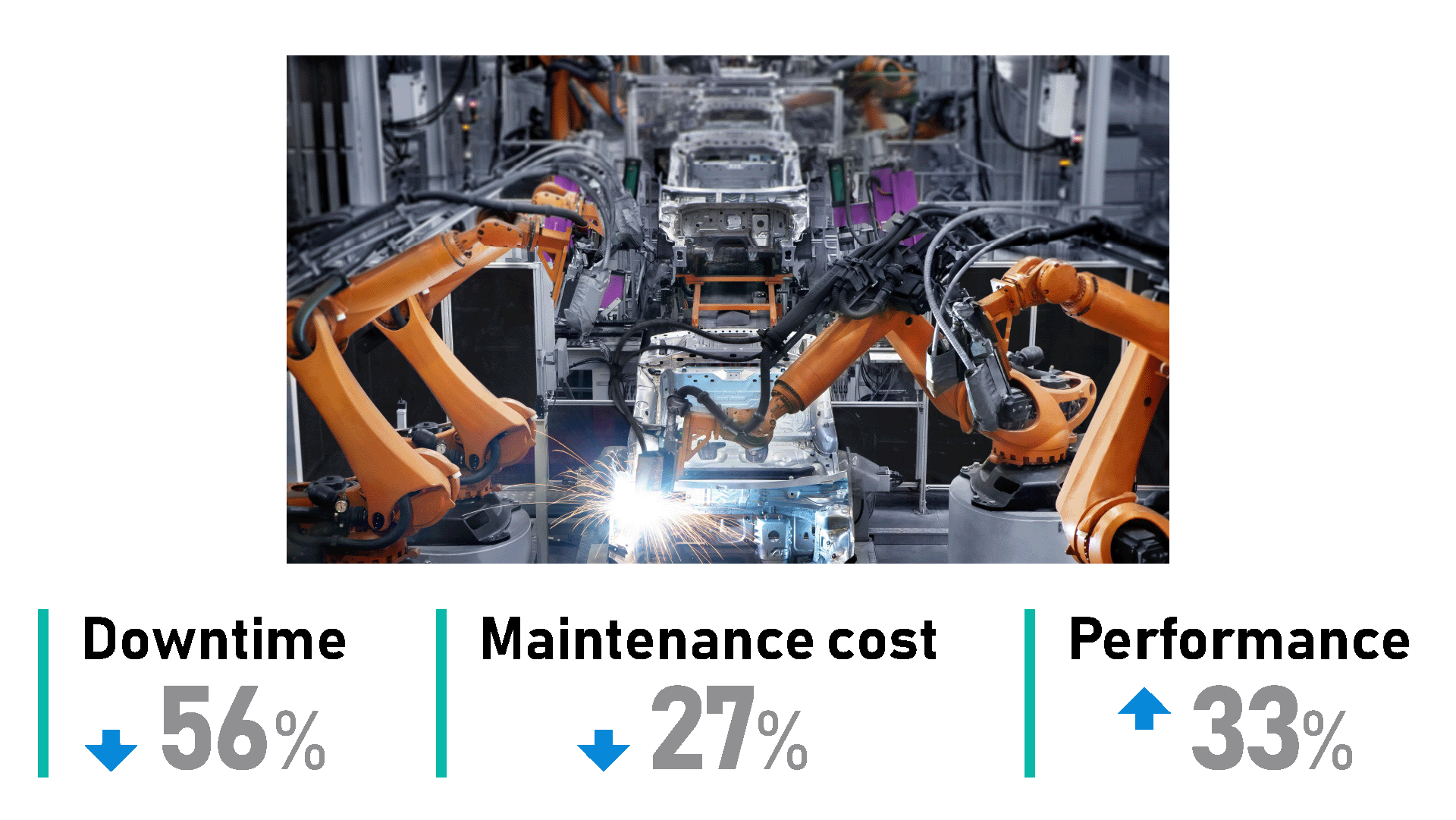

Greatly Improved Productivity in Automotive Parts Manufacturing

In the automotive parts industry, highly automated production lines are prevalent. In this specific case, a well-known automotive parts manufacturer sought assistance from Advantech iFactory to optimize their automated equipment and boost productivity. Our recommendation focused on two key aspects: the diversity of equipment and the lack of a unified standard for determining equipment capabilities. Furthermore, ensuring timely notification of equipment abnormalities emerged as one of the top three priorities that required attention and resolution.

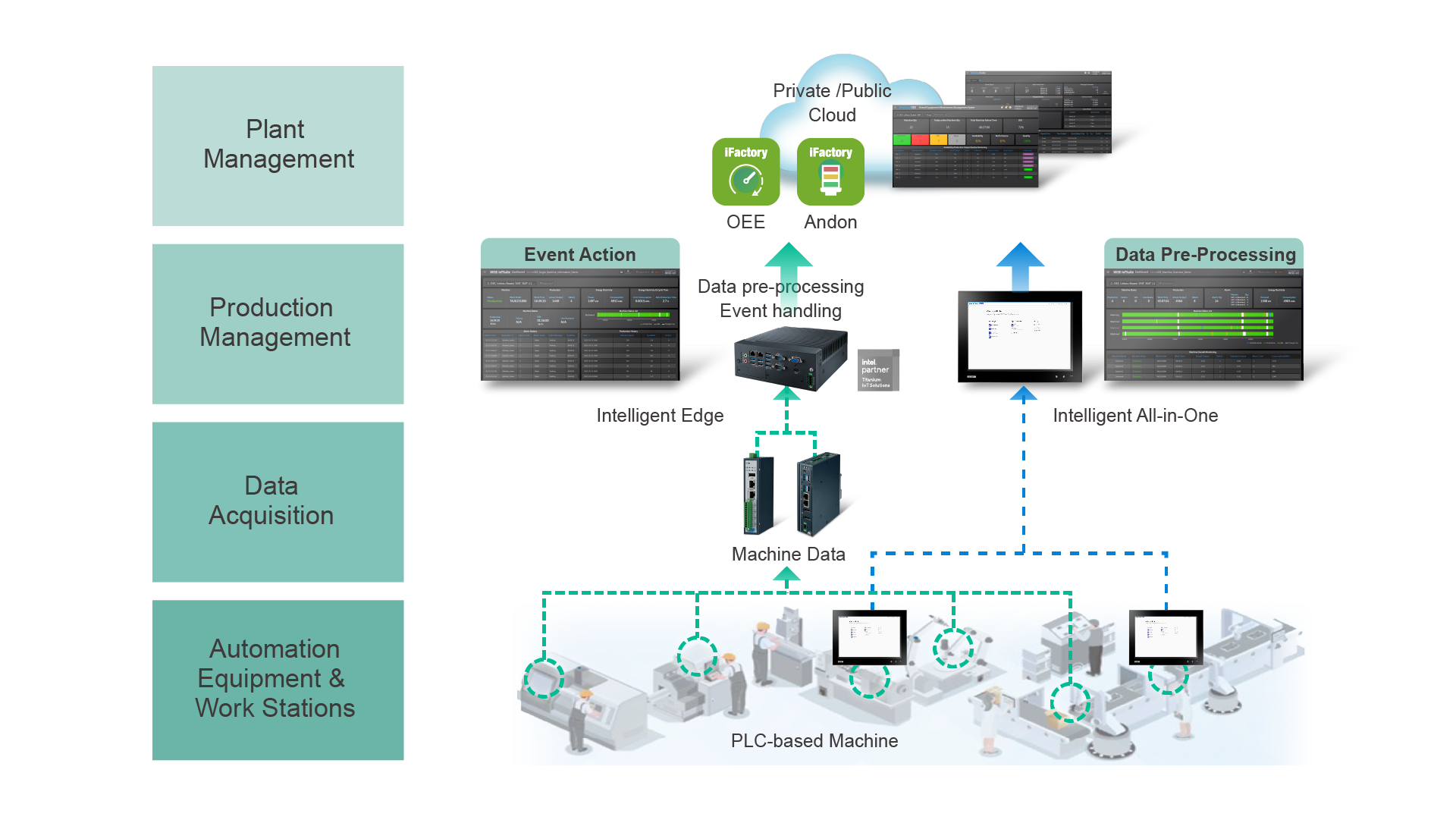

Design for Automation Service Providers and Manufacturers

Quick Response System Diagram

Intelligent Software Suite for the Quick Response Starter Package

Industrial Apps

OEE App

- The OEE (Overall Equipment Efficiency management) App monitors equipment status in real time, providing essential information such as production quality and ratios through data acquisition and dashboard presentation.

Andon App

- Andon, an important management tool used in lean manufacturing, automates the process of sending alerts when issues arise. This enables swift response, time savings, improved control, cost reduction, and enhanced data collection for better analysis.

Edge Devices

Computing & Protocol GatewayComputing & Protocol Gateways

Computing & Protocol GatewayComputing & Protocol GatewaysAdvantech offers a multitude of computing platforms to fit different edge computing needs. There is also an add-on protocol suite that collects data from different controller brands while still remaining a programmable edge platform.

Edge-Solution-Ready Package

Edge-Solution-Ready PackageHigh-performance, ready-to-run data acquisition, dashboard, and preinstalled software for real-time monitoring and OEE/Andon.

Edge-Solution-Ready PackageEdge Device with Touch Panel

Edge-Solution-Ready PackageEdge Device with Touch PanelWith the built-in touchscreen, abnormalities can be reported without the need for additional management and cost associated with a touch device.